Recycling. It’s in our own hands.

2019 is the year we’re taking action.

This week the UK is celebrating Recycle Week, now in its 17thyear. More than 60% of UK households recycle more than they were a year ago, yet the boost has been accompanied by an increase in recycling contamination.

What is recycling contamination? Are policy gaps and a lack of investment and infrastructure trapping UK into exporting recycling streams to developing nations? Recyclable doesn’t equal sustainable – do you know the difference? Read on to find out what were our challenges in finding sustainable packaging and how we at Albiva went about tackling these.

Recyclable doesn't equal sustainable.

Sustainability impacts every aspect of a package—from the source of its raw materials to its end of life—and as such has proven to be an incredibly complex issue.

Knowing our supply chain and have the transparency on where our packaging materials come from was important to make sure we are using responsibly sourced packaging materials.

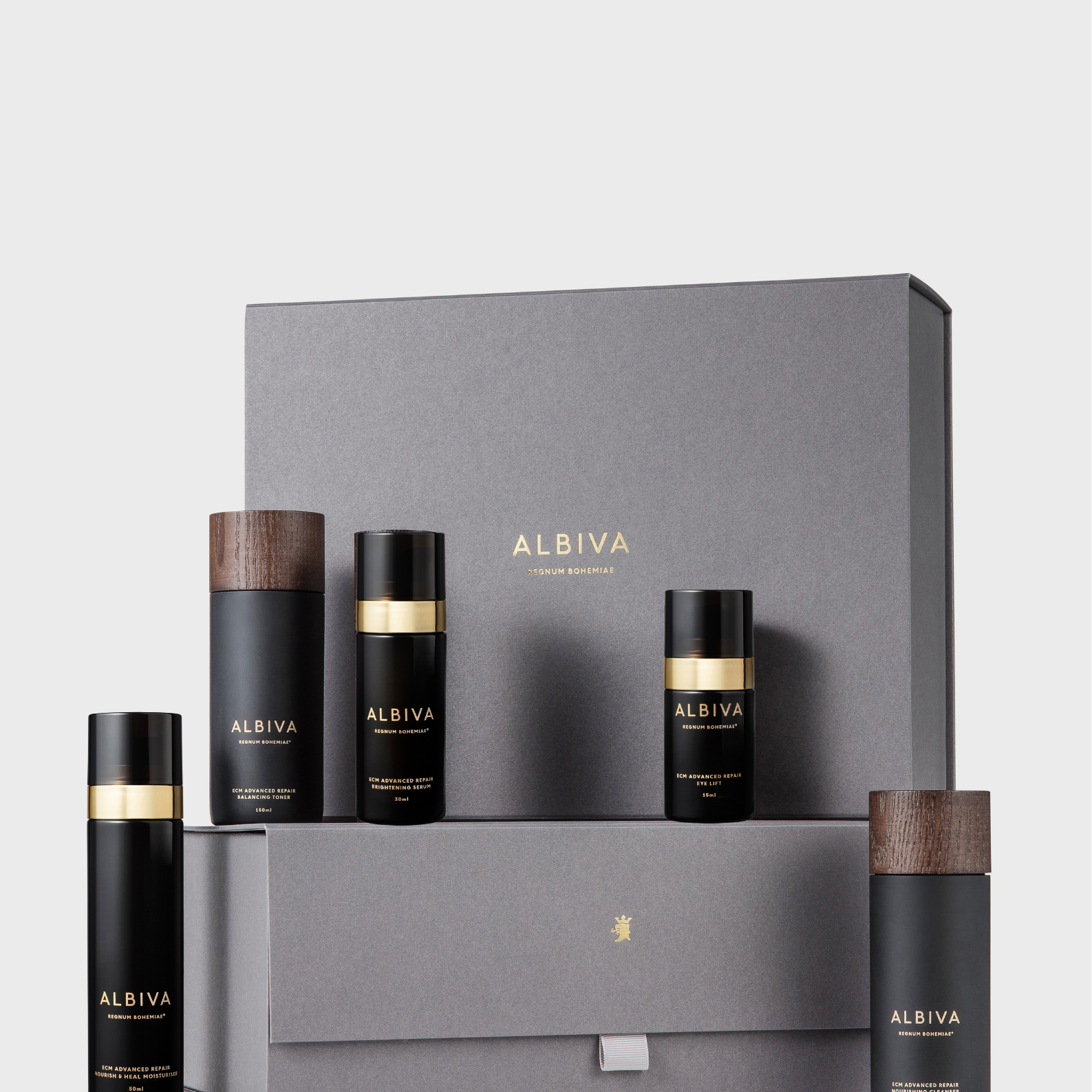

Sometimes a packaging design starts off eco-friendly, but additions like polymer tie straps, cellophane viewing panes, and foil inserts will make them unsustainable again. The greater its mix of materials, the less recyclable it is.

Unfortunately, making the first best impression is crucial in the case of product packaging to attract customers. The moment a product reaches a retail shelf, it becomes vital for it to catch the eye of the customer. Product packaging plays a prime factor in shaping the perception of a customer. It is for this reason, when choosing our packaging three years ago, we found most of the beauty industry packaging to be using film lamination – a thin layer of plastic on top of the paper. It is used to make our packaging ‘glossy’ (it also gives the packaging durability and protection from dirt).

Mostly, paper can’t be recycled if it’s mixed with other materials. Even if some recycling centres have machinery that separate the plastic lining from the paper, this process is resources intensive (electricity, water usage, emissions), increasing the negative impact it has on the environment.

When it comes to the contamination of materials, at the beginning of 2018, China, the main global buyer of recycled paper products, stopped accepting any paper bales with a 1% contamination rate or higher. According to our research, the best recycling facilities in UK are operating at a 4-5% contamination rate.

We wanted to simplify our supply chain as much as possible, and we wanted our packaging to be free from plastic coating and other contaminants, such as glue. We have therefore taken the decision to buy a hand made, raw and 100% biodegradable paper from G.F. Smith (UK company) and manufacture the boxes ourselves. To further reduce resources and our carbon footprint, after the paper is cut, our boxes are folded by hand. The construction of our boxes and the product completion (placing product into the box) is all done under one roof, positively impacting our carbon footprint.

Plastic vs Glass and is one better than other?

Plastics have been demonised but sometimes they are the more sustainable option. For example, aluminium and glass, are more carbon intensive to produce than plastic. Glass is also heavier to ship, contributing to higher CO2 emissions. The glass needs to be sorted by colour and washed to remove any impurities. It is then crushed and melted, all requiring energy to water which is a drain on natural resources.

The UK business sector still has a lot of work to do to recycle glass – bars, restaurants and pubs currently throw away over 200,000 tonnes of glass every year into landfill.

Despite all the good qualities of glass packaging, glass recycling is struggling. So, what’s the problem with glass?

The problems begin with the collection process, where glass breaks when it is placed in collection vehicles. With single-stream programs, broken glass is mixed up with tons of other recyclables and is difficult to sort. Even with dual-stream recycling programs and drop-off centers where materials are collected separately, glass can be a problem. At recycling centers glass is hard on equipment, creating wear on conveyor belts, screens and other moving parts. As paper and cardboard mills become more stringent on quality and more attention is given to material contamination, many recycling centres have been dropping glass from the list of acceptable items.

Reducing, reusing and recycling whichever material you prefer.

In acknowledging the heavy carbon footprint of glass and challenges with it’s recycling, it is perhaps more important to practice sustainable habits than favour one material over the other?

- Tags: Beauty Sustainability Technology